What is Fermenter and How Does It Work?

A fermenter, also known as a bioreactor, is a specialized vessel or apparatus designed to provide an optimal environment for microorganisms to carry out fermentation processes, converting organic compounds into desirable products. A fermenter is a specialized bioreactor used for the cultivation of microorganisms, cells, or enzymes under controlled conditions to produce biochemical products. It is widely used in industries such as pharmaceuticals, biotechnology, food, and beverage production.

What is a Fermenter?

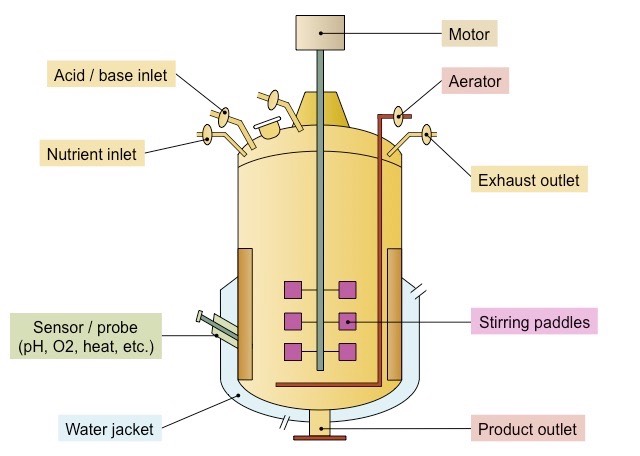

A fermenter is a device that uses microorganisms to create products like alcohol, organic acids, and gases. It’s also known as a bioreactor. It contains all of the components required for the commercial synthesis of compounds such as antibiotics, enzymes, and drinks in a variety of sectors. The basic functional requirements of fermenters, including aseptic operation and containment, are then considered. Construction of a fermenter, with emphasis on the stirred tank reactor is discussed.

How Does a Fermenter Work?

Fermenters work by maintaining precise conditions needed for microbial or cell growth and metabolism. Here’s how a typical fermenter operates:

Inoculation: The fermenter is first filled with a nutrient medium, which can include water, sugars, salts, and other compounds necessary for growth. The microorganisms or cells are introduced into this medium to begin the fermentation process.

Control of Environmental Factors: The fermenter is equipped with various sensors to monitor critical parameters like pH, temperature, oxygen levels, and agitation speed. Maintaining these parameters at optimal levels is key to ensuring maximum production efficiency and preventing contamination.

Aeration and Mixing: Depending on whether the fermentation process is aerobic or anaerobic, oxygen or other gases are supplied. The fermenter often includes spargers or diffusers to efficiently mix the air with the medium. Agitation also ensures uniform distribution of nutrients and cells throughout the medium.

Harvesting: After the fermentation process reaches its peak or the desired product is produced, the contents of the fermenter are harvested. This might involve separating cells, purifying the product, or both.

Sterilization and Maintenance: To avoid contamination, fermenters are regularly sterilized. The sterility ensures that only the desired microorganisms are present, preventing unwanted species from affecting the fermentation process.

Types of Fermenters

Different types of fermenters are designed to suit specific applications:

- Stirred-Tank Fermenter (STF): Commonly used in pharmaceutical and industrial applications, this type has an agitator to mix the contents and provide uniform conditions.

- Air-Lift Fermenter: Known for its gentle mixing action, it is preferred for culturing delicate cells.

- Bubble Column Fermenter: This is often used for aerobic fermentation, relying on bubbles to mix the medium and supply oxygen.

Applications of Fermenters in Pharma

Fermenters are extensively used in pharmaceutical production to generate bio-based drugs, including:

- Antibiotics: Penicillin, streptomycin, and other antibiotics are produced via microbial fermentation.

- Enzymes: Fermenters are crucial in the production of enzymes used in therapies, diagnostics, and industrial processes.

- Vaccines: Some vaccines, including those for hepatitis and influenza, are produced using fermentation technology.

Why Choose INSTECH Pharma for Your Fermentation Needs?

At INSTECH Pharma, we are dedicated to providing high-quality fermenters tailored to your specific requirements. With advanced technology and a focus on efficiency, we ensure that your fermentation processes run smoothly, from pilot-scale to industrial-scale production.

Contact Us

For more information on our fermenters and other biotechnological solutions, reach out to us today:

📞 +91-9812014170, +91-9873069138