Planetary Mixer Working Principle & Pharmaceutical Applications

Planetary Mixer Manufacturer

Planetary Mixer Machine: Working Principle & Pharmaceutical Applications

At INSTECH Pharma, we understand the critical role that efficient mixing plays in pharmaceutical manufacturing. Our state-of-the-art planetary mixers are designed to deliver high-quality results for a wide range of pharmaceutical applications. In this blog, we will explore the working principle of planetary mixers and how they are used in the pharmaceutical industry to enhance product quality and efficiency.

What is a Planetary Mixer?

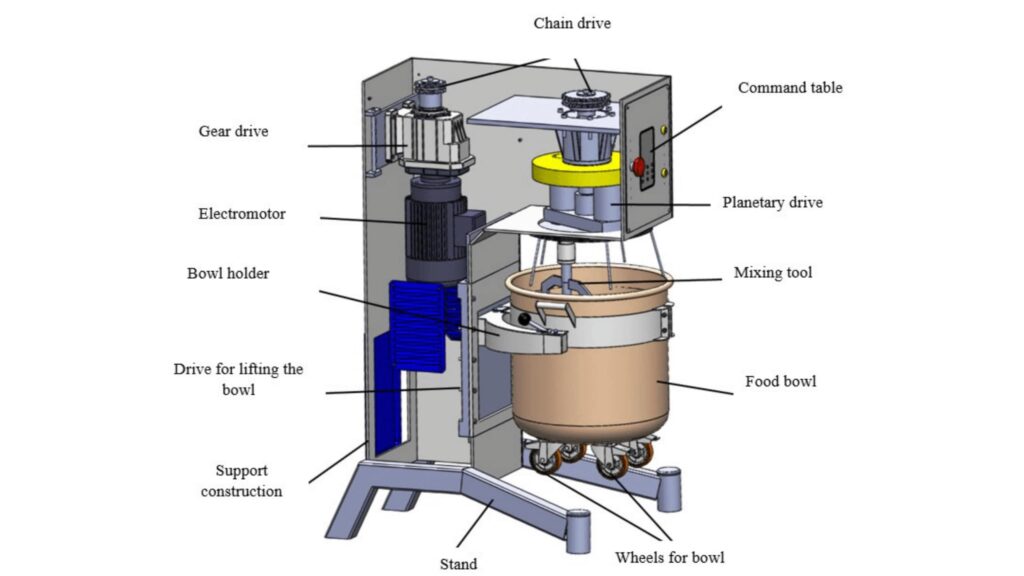

A planetary mixer is a type of mixing equipment that provides highly efficient and homogeneous mixing of materials. Unlike conventional mixers, planetary mixers are designed with a unique planetary motion, ensuring thorough mixing of substances, especially for viscous and cohesive materials. They are equipped with rotating blades that move both around their own axis and around the bowl, similar to the planetary motion of celestial bodies.

This dual motion—referred to as planetary motion—ensures uniform mixing of materials from all directions, making planetary mixers ideal for a variety of applications in the pharmaceutical industry.

Planetary Mixer Working Principle

The working principle of a planetary mixer is simple yet effective. The central component of the mixer is a rotating shaft, to which mixing blades or paddles are attached. These blades rotate both around the bowl and on their own axis, creating a two-fold motion that helps mix materials thoroughly.

- Rotating Motion: The mixer’s central shaft rotates around the bowl, and the mixing tools attached to it follow this motion, similar to how planets orbit around the sun.

- Counter-Rotating Action: In many planetary mixers, the blades also rotate in the opposite direction from the mixer’s rotation. This ensures that the materials are constantly being lifted, folded, and sheared, preventing the formation of lumps and ensuring uniform blending of all ingredients.

This unique mixing process allows planetary mixers to work efficiently with a range of materials, including powders, pastes, creams, and suspensions, ensuring the creation of uniform mixtures every time.

Pharmaceutical Applications of Planetary Mixers

Planetary mixers are widely used in the pharmaceutical industry due to their ability to handle various materials, including powders, liquids, and semi-solids, with precision. Below are some key pharmaceutical applications where planetary mixers excel:

1. Creams, Ointments, and Emulsions

Planetary mixers are ideal for manufacturing creams, lotions, ointments, and emulsions. These formulations require gentle mixing to ensure that active pharmaceutical ingredients (APIs) are evenly distributed in the base material, creating a smooth and homogeneous product. Planetary mixers are capable of blending ingredients of different viscosities and densities, providing high-quality emulsions with stable consistency.

2. Granulation

In the pharmaceutical industry, granulation is a crucial step in tablet and capsule production. Planetary mixers are used in both dry and wet granulation processes to mix powders with liquids, forming granules of consistent size and quality. The even distribution of ingredients ensures that the final granules exhibit uniformity, which is essential for precise dosing and effective drug delivery.

3. Powder Blending

Planetary mixers are used to blend a wide variety of powders in pharmaceutical formulations. The unique motion ensures that powders are mixed thoroughly, preventing segregation or clumping. This is essential when working with APIs and excipients that need to be evenly distributed throughout the batch.

4. Suspensions and Pastes

For the production of suspensions and pastes, planetary mixers provide a consistent and uniform mix, ensuring that the solid particles are evenly dispersed in the liquid medium. This is especially important for formulations like syrups, suspensions, and gel-based products, where even distribution of active ingredients is critical for effective drug delivery.

5. High-Viscosity Material Mixing

Planetary mixers are particularly effective when working with high-viscosity materials such as pastes, gels, and semi-solids. The intense mixing action of the blades ensures that even the most viscous materials are thoroughly mixed, creating a homogeneous final product.

Why Choose INSTECH Pharma’s Planetary Mixers?

At INSTECH Pharma, we offer advanced planetary mixers that are designed to meet the rigorous demands of the pharmaceutical industry. Our mixers provide superior mixing capabilities, ensuring consistency and quality in every batch. Some of the key benefits of our planetary mixers include:

- Efficient Mixing: The dual motion ensures even and thorough mixing, even with high-viscosity and complex materials.

- Customization: Our mixers can be tailored to meet the specific needs of your production process.

- Durability: Built with high-quality materials, our mixers are designed for long-lasting performance and reliability.

- Compliance: Our mixers are designed in compliance with industry standards and regulations, ensuring that your manufacturing processes meet the highest quality requirements.

Conclusion

Planetary mixers play a vital role in pharmaceutical manufacturing, ensuring that active ingredients are evenly distributed and mixed with precision. Whether you’re producing creams, ointments, granules, or suspensions, INSTECH Pharma’s planetary mixers can help streamline your production process and deliver consistent, high-quality results.

If you’re interested in learning more about our planetary mixers or would like to discuss how they can enhance your pharmaceutical manufacturing, contact us at INSTECH Pharma. Our team of experts is here to assist you in finding the perfect solution for your mixing needs.

INSTECH Pharma

Hall no. 5, Plot no. 173/3, Rajendra Nagar Industrial Area, Ghaziabad (U.P.), Bharat PIN 201007

Phone: +91-9812014170, +91-9873069138

Email: info@pharmaceutech.com