Which manufacturer provides the best ribbon blender machine in India?

Ribbon Blender Machine Advantages and Disadvantages

When it comes to efficient and uniform blending of powders and granules, Instech Pharma stands out as a trusted Ribbon Blender Machine Manufacturers in India. With cutting-edge technology, precision engineering, and a customer-centric approach, we deliver the finest blending equipment tailored to your industrial needs.

What is a Ribbon Blender Machine?

A ribbon blender machine is a versatile and efficient industrial mixing machine used for blending dry powders, granules, and other solid materials. It consists of a U-shaped horizontal trough and a rotating shaft equipped with helical ribbons, which move materials in both directions to achieve a uniform mix. The inner and outer ribbons rotate at different speeds, ensuring thorough blending with minimal dead spots.

Ribbon blender machines are used in industries like food processing, pharmaceuticals, chemicals, and construction. They are ideal for mixing powders, spices, protein supplements, fertilizers, and even plastic resins. The machine operates with high efficiency, requiring low maintenance while providing consistent results.

These blenders come in several sizes and configurations, including stainless steel or mild steel construction, depending on the application. Some models also include features like spray nozzles for liquid addition, heating or cooling jackets, and vacuum operations for sensitive materials.

Types Of Ribbon Blender Machine

There are two types of ribbon blenders such as horizontal and vertical. Ribbon blenders are mixing machines that blend dry powders, granules, and other solid materials.

Horizontal Ribbon Blender Machine

A horizontal ribbon blender machine is an industrial mixing machine designed to efficiently blend dry powders, granules, and other solid materials. It features a U-shaped horizontal trough with a central shaft fitted with helical ribbons that rotate to mix materials evenly. The ribbons consist of both inner and outer blades that move materials in opposite directions, ensuring a homogeneous blend with minimal dead zones.

Vertical Ribbon Blender Machine

A vertical ribbon blender machine is a mixing machine designed for efficiently blending dry powders, granules, and other bulk materials. Unlike horizontal ribbon blenders, it features a vertical conical or cylindrical chamber with a centrally mounted ribbon agitator that moves materials in an upward and downward motion, ensuring uniform mixing.

Working Principle Of Ribbon Blender Machine

A ribbon blender machine works by using a double helix ribbon agitator to mix materials in a U-shaped vessel. The ribbons rotate at high speed, creating a convective mixing pattern that moves materials in two directions. This process results in a smooth, homogenous mixture.

- The outer ribbon moves materials from both ends of the vessel to the center.

- The inner ribbon moves materials from the center of the vessel to both ends.

- The ribbons rotate at high speed, creating a convective mixing pattern.

- The countercurrent and radial motion of the ribbons quickly produces a smooth, homogenous mixture.

Why Choose Instech Pharma For Ribbon Blender Machine Manufacturer in India ?

When it comes to high-quality Instech Pharma provides one of the best ribbon blender machine manufacturers in India. We are a trusted and reliable name in the industry. With 15+ years of experience in precision engineering, we specialize in designing and manufacturing horizontal and vertical ribbon blenders for various industries, including pharmaceuticals, food processing, chemicals, and cosmetics.

Here Are Reasons to Choose Instech Pharma:

- Superior Quality and Precision Engineering : Our ribbon blenders are made from high-grade stainless steel (SS 304 & SS 316), ensuring durability, corrosion resistance, and compliance with international quality standards. We focus on precision engineering to provide efficient mixing solutions.

- Customization Options : We understand that every industry has unique mixing requirements. That’s why we offer custom-built ribbon blenders with features such as heating/cooling jackets, vacuum systems, liquid spray nozzles, and variable speed control for optimized performance.

- Advanced Manufacturing Technology : With state-of-the-art CNC machinery and automated production lines, we manufacture ribbon blenders with high accuracy, ensuring homogeneous mixing, reduced material wastage, and consistent batch quality.

- GMP & FDA Compliance : For the pharmaceutical and food industries, compliance with GMP (Good Manufacturing Practices) and FDA regulations is crucial. Our ribbon blenders are designed to meet strict hygiene and safety standards, with smooth internal surfaces for easy cleaning and minimal contamination risk.

- Energy-Efficient and Cost-Effective Solutions : Our ribbon blenders are designed for low power consumption and high efficiency, reducing operational costs while ensuring optimal mixing performance.

- Timely Delivery & Excellent After-Sales Support : We value our clients’ time. We ensure on-time delivery and provide comprehensive after-sales support, including installation assistance, maintenance services, and spare parts availability.

Applications of Ribbon Blenders Machine

- Pharmaceutical: Blending powders for formulations

- Food & Beverage: Mixing ingredients like spices, flour, and baking powders

- Chemical: Homogenizing dry chemicals and fertilizers

- Cosmetics: Preparing powders and granules for cosmetic formulations

- Plastic & Resins: Uniform mixing of additives and polymers

Features of Instech Pharma Ribbon Blenders Machines

- U-Shaped Trough: Ensures consistent and uniform mixing.

- Helical Ribbon Design: Counterflow movement for precise blending.

- Easy Discharge: Quick material removal with minimal residue.

- Hygienic Construction: Easy-to-clean surfaces for contamination-free operation.

- Safety Features: Built-in mechanisms to ensure operator safety.

Why Industries Trust Instech Pharma

Instech Pharma as your ribbon blender manufacturer guarantees quality, efficiency, and reliability. Our commitment to innovation, precision, and customer satisfaction makes us the preferred choice for industries worldwide. We understand industry requirements and offer:

- Reliable performance

- Competitive Pricing

- On-time delivery

- Exceptional after-sales support

Read More : Ribbon Blender Machine Advantages and Disadvantages

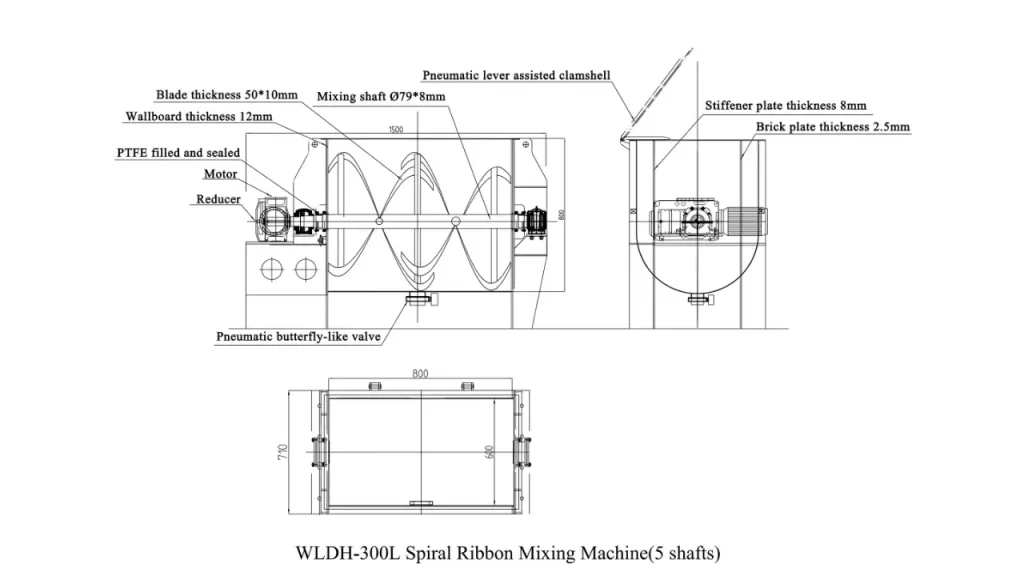

Ribbon Blender Diagram

Conclusion

Looking for reliable Ribbon Blender Manufacturers? Instech Pharma is here to provide top-quality blending solutions for your specific industrial needs. Get in touch with our team for a free consultation and quote. For industries that demand precision, consistency, and durability in mixing, Instech Pharma is the name you can trust. Our Ribbon Blenders are crafted to meet the highest quality standards, ensuring seamless performance across applications. Choose Instech Pharma for all your blending equipment needs!