In the pharmaceutical and healthcare industries, sterilization is a critical process that ensures the elimination of microbial contaminants from equipment, instruments, and packaging materials. Among the various sterilization techniques, dry heat sterilization is widely recognized for its effectiveness in achieving sterility. This method is particularly suitable for materials that can withstand high temperatures without degradation. In this article, we will explore dry heat sterilization methods, their applications, advantages, limitations, and best practices.

What is Dry Heat Sterilization?

Dry heat sterilization is a process that uses high temperatures to kill microorganisms by oxidation. Unlike moist heat sterilization, which relies on steam, dry heat sterilization operates in the absence of moisture, making it ideal for materials that are sensitive to moisture or corrosion. The process is commonly used in pharmaceutical industries, medical laboratories, and manufacturing units where sterility is paramount.

Key Methods of Dry Heat Sterilization

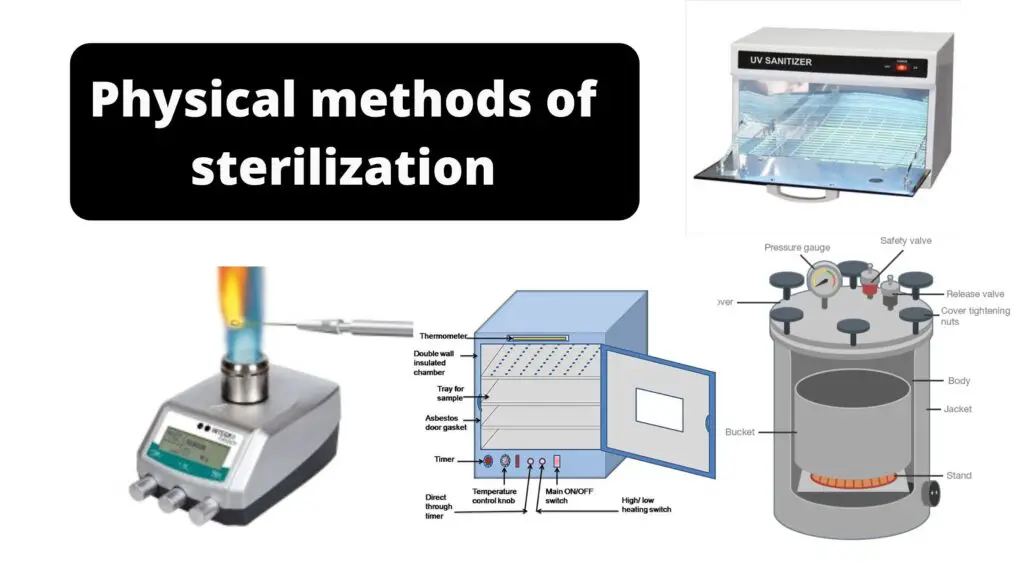

There are several methods of dry heat sterilization, each with specific applications and operational conditions. The most commonly used methods include:

1. Hot Air Oven Sterilization

The hot air oven is one of the most commonly used dry heat sterilization methods. It operates by circulating heated air within a closed chamber to maintain a uniform temperature. The key parameters of this process include:

- Temperature: 160°C to 180°C

- Exposure Time: 1 to 2 hours

- Mode of Action: Oxidation and protein denaturation

This method is widely used for sterilizing glassware, metal instruments, and powders that are not heat-sensitive.

2. Flaming

Flaming is a rapid sterilization method that involves exposing instruments directly to an open flame, such as a Bunsen burner. This technique is commonly used in microbiology laboratories for sterilizing inoculation loops, forceps, and needles. The high temperature instantly kills microorganisms through incineration.

3. Incineration

Incineration is an extreme form of dry heat sterilization used for the disposal of contaminated medical and pharmaceutical waste. This process involves burning the waste material at temperatures exceeding 1000°C, completely destroying all microbial life. It is an effective method for handling biohazardous waste but is not suitable for reusable items.

4. Radiation Sterilization with Infrared Heat

Infrared heat sterilization is a specialized dry heat method that utilizes infrared radiation to generate heat. This technique is particularly useful for sterilizing surfaces and components in continuous production lines, such as pharmaceutical bottles and packaging materials.

Advantages of Dry Heat Sterilization

Dry heat sterilization offers several benefits, making it a preferred choice in various industrial applications:

- Non-Corrosive: Ideal for sterilizing metal instruments and glassware without causing rust or damage.

- Efficient for Heat-Stable Materials: Suitable for items that cannot tolerate moisture or steam.

- No Residual Moisture: Unlike moist heat sterilization, there is no risk of moisture retention, which can be crucial for certain pharmaceutical products.

- Effective Against Spores and Pyrogens: High temperatures effectively destroy bacterial spores and heat-resistant contaminants.

Limitations of Dry Heat Sterilization

Despite its advantages, dry heat sterilization has some limitations:

- Longer Processing Time: Requires higher temperatures and extended exposure periods compared to moist heat sterilization.

- Energy-Intensive: Higher energy consumption due to prolonged heating cycles.

- Limited Material Compatibility: Not suitable for heat-sensitive materials, such as plastics and certain pharmaceuticals.

Best Practices for Dry Heat Sterilization

To ensure the effectiveness of dry heat sterilization, it is essential to follow best practices:

- Proper Loading of the Sterilizer: Arrange items to allow uniform heat distribution and airflow.

- Temperature and Time Monitoring: Use calibrated thermometers and timers to ensure the correct exposure conditions.

- Validation and Documentation: Conduct regular validation tests, including biological indicators, to verify sterility.

- Routine Maintenance: Regularly inspect and maintain sterilization equipment to ensure optimal performance.

- Compliance with Regulatory Guidelines: Adhere to industry standards such as USP, GMP, and FDA guidelines for sterilization practices.

Applications of Dry Heat Sterilization in the Pharmaceutical Industry

The pharmaceutical industry relies on dry heat sterilization for various applications, including:

- Sterilization of Glass Containers: Vials, ampoules, and bottles used in drug packaging.

- Processing of Oily and Powdered Drugs: Certain pharmaceutical compounds that cannot be sterilized using moist heat.

- Decontamination of Laboratory Instruments: Metal tools and glassware used in research and quality control labs.

Conclusion

Dry heat sterilization is a vital method in the pharmaceutical and healthcare industries, providing an effective and reliable means of eliminating microbial contamination. While it has certain limitations, its benefits make it an essential sterilization technique for specific applications. By understanding the different dry heat sterilization methods and following best practices, pharmaceutical manufacturers can ensure product safety and regulatory compliance.