Ribbon Blender Machine Advantages and Disadvantages

Ribbon Blender Machine Advantages and Disadvantages

Ribbon Blender Advantages and Disadvantages

At INSTECH Pharma, we specialize in providing high-quality mixing solutions for a wide range of industries, including pharmaceuticals, food, chemicals, and cosmetics. One of the most popular and versatile mixing machines used in these industries is the Ribbon Blender Machine. This piece of equipment is renowned for its ability to blend a variety of materials efficiently. However, like any machinery, it has its strengths and weaknesses. In this blog, we will delve into the advantages and disadvantages of Ribbon Blender Machines, helping you make an informed decision when selecting the right equipment for your operations.

Ribbon Blender Machine Capacity:

The capacity of a Ribbon Blender Machine can vary significantly depending on the specific needs of the manufacturing process. Typically, the capacity of these machines ranges from small-scale lab units (around 10 to 50 liters) to large-scale industrial models capable of handling hundreds or even thousands of liters of material.

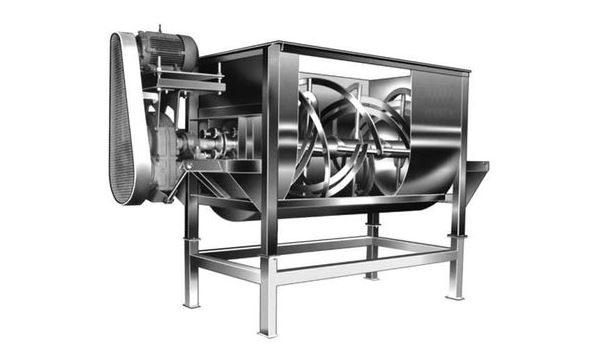

Ribbon Blender Diagram:

U-shaped Trough: This is the main body of the blender where materials are loaded and mixed. It’s usually made of stainless steel for durability and hygiene.

Ribbon Agitator: The two helical ribbons (inner and outer) mounted on a shaft that runs the length of the blender. The ribbons ensure the movement of material in both axial and radial directions, promoting thorough blending.

Inlet and Outlet Ports: The inlet port allows materials to be added into the blender, while the outlet port allows for the discharge of the finished blend.

Ribbon Blender Machine Parts:

A Ribbon Blender Machine consists of several key components, each designed to perform a specific function in the mixing process. Here are the primary parts of a Ribbon Blender:

Trough: The trough is the main container or body of the Ribbon Blender. It is typically U-shaped and made of stainless steel to facilitate easy cleaning and durability. The trough holds the material to be blended.

Ribbon Agitators (Inner and Outer): These are the primary moving parts of the blender. The outer ribbon pushes the material from the center of the trough to the ends, and the inner ribbon brings it back to the center. This motion ensures a thorough mix.

Advantages of Ribbon Blender Machines

Efficient and Uniform Mixing: The primary advantage of a Ribbon Blender Machine is its ability to deliver consistent and uniform blending. The unique design of the ribbon agitator provides both radial and axial mixing, ensuring that the materials are evenly distributed throughout the blender. This results in minimal segregation and improved product quality, making it an ideal choice for industries like pharmaceuticals and food processing, where uniformity is critical.

Versatility in Material Processing: A Ribbon Blender Machine is highly versatile, capable of handling a wide range of materials, including dry powders, granules, and even pastes or slurries. This makes it a go-to solution for various industries, such as pharmaceuticals, chemicals, and cosmetics, where different types of raw materials need to be mixed efficiently.

Gentle Mixing for Sensitive Materials: Unlike some other mixing machines, Ribbon Blenders offer a relatively gentle blending action, which prevents excessive shear forces that could damage delicate or sensitive materials. This is particularly beneficial in industries like pharmaceutical manufacturing, where active ingredients must remain intact and undamaged during the mixing process.

High Capacity and Scalability: Ribbon Blenders are available in a variety of sizes, including large-scale models that can accommodate significant quantities of material. This scalability makes them ideal for high-volume production in industries where large batch sizes are required, such as in pharmaceutical manufacturing or bulk food production.

Cost-Effective Solution: When compared to other industrial mixers, Ribbon Blenders are relatively cost-effective. With a lower initial investment and low maintenance costs, these machines offer long-term value. Their durable construction ensures they can withstand heavy use, which results in a longer operational life, reducing overall costs for businesses in the food and chemical industries.

Easy to Clean and Maintain: A significant benefit of the Ribbon Blender Machine is its design, which allows for easy cleaning and maintenance. This is particularly important in industries like pharmaceuticals and food processing, where hygiene standards are stringent. The simple design means that maintenance can be performed quickly and with minimal downtime.

Customizable Features: Many Ribbon Blender Machines can be customized to meet specific process requirements. Options such as heating or cooling jackets, vacuum systems, and anti-corrosive linings can be added to tailor the equipment for specialized tasks, such as mixing heat-sensitive ingredients or blending corrosive substances.

Disadvantages of Ribbon Blender Machines

Limited Homogeneity for Fine Powders: Although Ribbon Blenders are highly effective for most materials, achieving perfect homogeneity with fine powders or sticky substances can be challenging. In some cases, the finer powders may not blend as uniformly as desired, leading to slight segregation or inconsistency in the final product.

High Energy Consumption: Ribbon Blenders tend to consume a considerable amount of energy, particularly in large-scale operations where high volumes of materials are being processed. This could result in increased energy costs, which may be a concern for companies looking to optimize their operational expenses.

Risk of Overmixing: Prolonged or excessive mixing in a Ribbon Blender Machine can result in overmixing, potentially damaging sensitive materials or altering the texture of the product. It’s crucial to monitor the mixing time to ensure that the product is mixed to the desired consistency without compromising quality.

Not Ideal for Liquids: While Ribbon Blenders can handle some degree of liquid incorporation, they are not the best option for blending materials that are primarily liquid. Other types of blenders, such as planetary mixers or vertical blenders, may be more suitable for applications that require blending of large quantities of liquids or viscous materials.

Challenges with High Bulk Density Materials: Materials with a high bulk density can be challenging for Ribbon Blenders to mix effectively. When the material is too dense or heavy, the ribbon agitator may struggle to move it efficiently, which can result in uneven blending or incomplete mixing.

Wear and Tear: The constant friction between the ribbon blades and the materials being mixed can lead to wear and tear over time. For industries that rely on Ribbon Blenders for high-volume production, regular maintenance and periodic replacement of components like the blades may be necessary, adding to operational costs.

Conclusion

At INSTECH Pharma, we understand that choosing the right mixing equipment is essential for maintaining the quality and efficiency of your production processes. The Ribbon Blender Machine is a popular choice for many industries due to its ability to provide efficient mixing, versatility, and cost-effectiveness. However, like any piece of equipment, it has its limitations, particularly when dealing with fine powders, high liquid content, or materials with high bulk density.

We are manufacturers of : Bioreactors , Bung Processor Cum sterilize , Ribbon Blenders , Planetary mixers, HPHV Steam Sterilizer (Autoclave), Dry Heat Sterilizer Manufacturer ,Isolator/Isolation Cabinet, Pass Box (Static and Dynamic).

By carefully weighing the advantages and disadvantages of Ribbon Blender Machines, you can make an informed decision that aligns with your specific production needs. For more information on how a Ribbon Blender Machine can improve your manufacturing process, or to inquire about other industrial mixing solutions, contact us at INSTECH Pharma today!

Incorporating the keyword “Ribbon Blender Machine Advantages and Disadvantages” throughout the content enhances its relevance for search engines while providing a comprehensive look at the pros and cons of this popular blending equipment. Whether you’re in the pharmaceutical, food, or chemical industry, understanding these factors can help you optimize your operations and choose the best mixing solution for your needs.

INSTECH Pharma

Hall no. 5, Plot no. 173/3, Rajendra Nagar Industrial Area, Ghaziabad (U.P.), Bharat PIN 201007

Phone: +91-9812014170, +91-9873069138

Email: info@pharmaceutech.com